Visit object:

From organic waste to transport fuel and environmentally friendly bio-fertilizer

Topic: Circular economy, Eco Governance, Green City, Green transport Company type: Public organisation

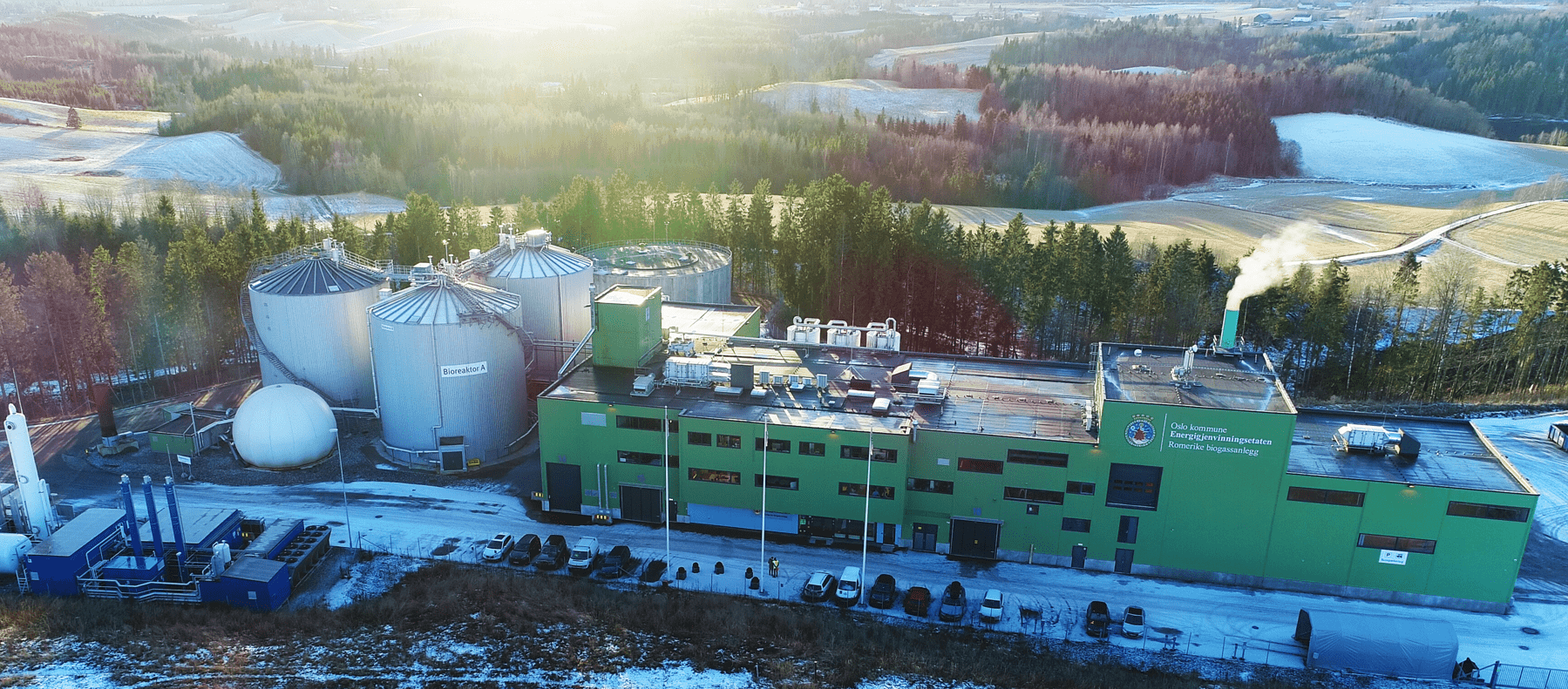

As part of its cycle-based waste management system, the City of Oslo has adopted biological treatment of source separated food waste. The biogas plant at Romerike is operated by the Waste-to-Energy Agency and is a major contributor to Oslo’s efforts to reduce greenhouse gas emissions.

The Waste-to-Energy agency has 140 employees in total and is subject to the Department of Transport and Environmental Affairs in the Municipality of Oslo.

The feedstock received at the Romerike biogas plant (RBA) is formed of both solid and liquid organic waste. By 2017 approximately 30.000 tonnes of food waste is processed by the plant.

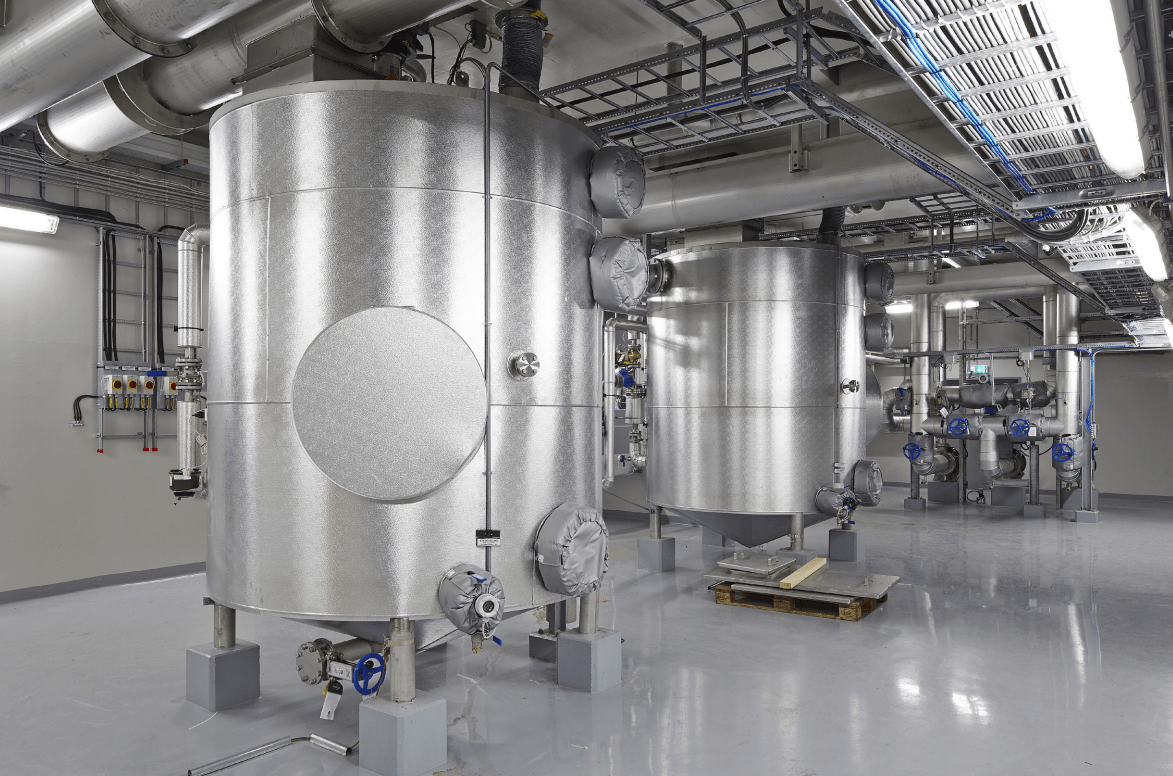

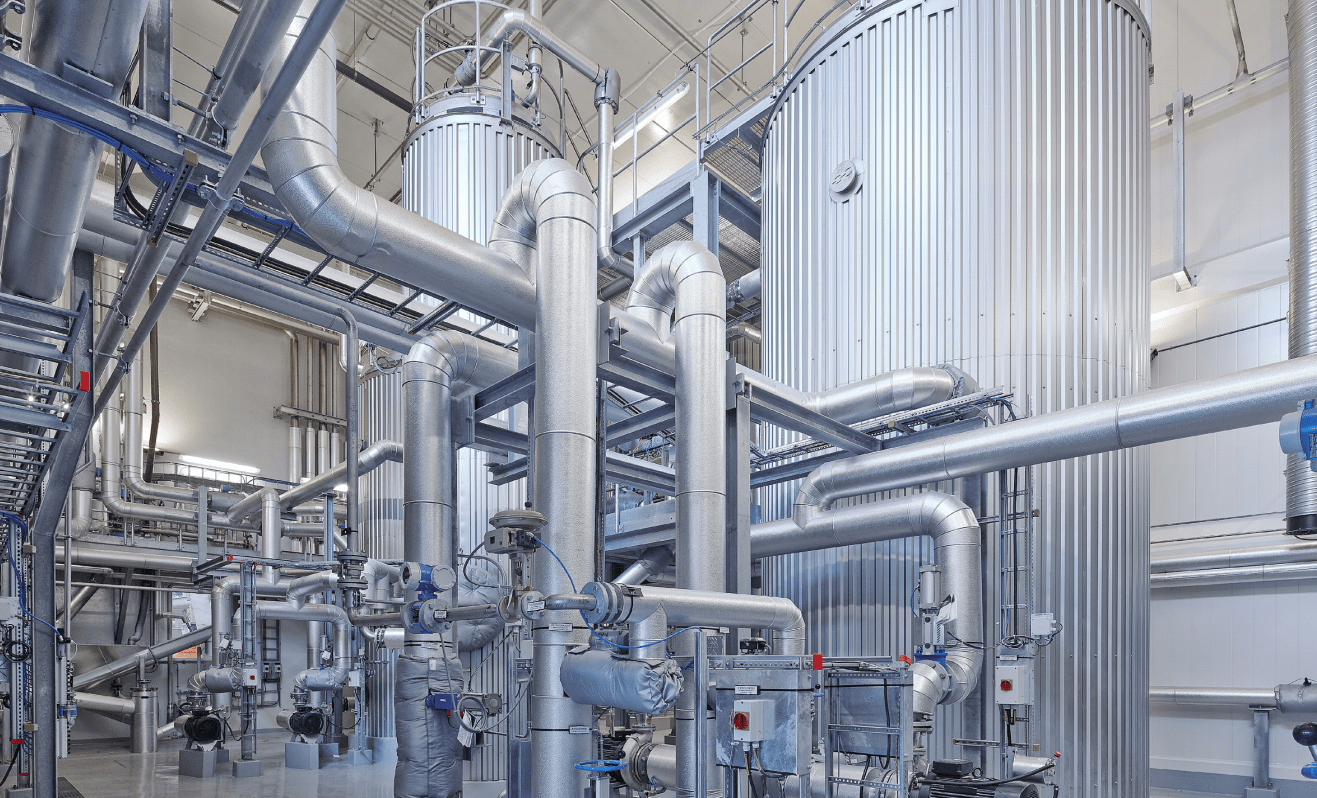

Biogas. The biogas plant is equipped with two bioreactors, each with a capacity of 3,200 m3. The pre-treated substrate is pumped into the reactor tanks and disintegrates by a bacterial culture in anaerobic conditions. The temperature in the reactor tank is 38°C, and the retention is about 24 days. This process is called thermal hydrolysis and is enabled by a Norwegian patented technology. The gas that occurs from this process consists of approx. 60% methane and 40% carbon dioxide.

The biogass plant is also equipped with a methane upgrading system which can upgrade the raw biogas to a purity of 99% methane. The upgraded methane is cooled down to -162⁰C and stored at a pressure of 2 bars. The gas is than used as fuel for public buses in Oslo.

Fertilizer. Food waste contains important nutrients, such as phosphorous, nitrogen and potassium, and should be retained in a natural life cycle. Therefore, RBA also produces three types of biofertilizer: liquid biofertilizer; bioconcentrate, and solid organic material. As the plant is located in an agricultural area, there is no need for long distance transport of the fertilizer in order to reach the customers. In this way, the cycle is closed at a regional level.